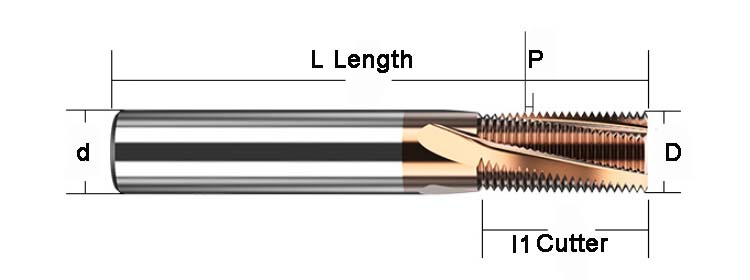

25mm Thread End Mill Milling Cutter Carbide End Mill Full Teeth

Product Details:

| Place of Origin: | China |

| Brand Name: | BWIN |

| Model Number: | M12x1.75-D9.8x30x75 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs/box |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plastic box |

| Delivery Time: | 7 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1-10000pcs 7days |

|

Detail Information |

|||

| Product Name: | Carbide Thread End Mill 25mm | Model: | 3flut Spiral Threading Endmill |

|---|---|---|---|

| Material: | Tungsten Carbide Indexable Milling Cutter | Workpiece: | Cast Iron/Steel/Stainless Steel/Aluminum |

| Usage: | Milling | Coating: | TiAICN |

| Angle Of Tooth: | 55°,60° | Feature: | High Cutter Tooth Strength |

| Application: | Milling Machine | Package: | 1pcs/Box |

| Highlight: | 25mm Thread End Mill,Carbide End Mill 25mm,Carbide End Mill Full Teeth |

||

Product Description

Threading Milling Cutter M12x1.75-D9.8x30x75 TiAICN Coated Full Teeth Carbide Thread End Mill

Quick Detail:

- High hardness

- High precision

- Good wear resistance

- Good finish

- Strong vibration resistance

- Long life

Description:

- Compared with the traditional thread processing method, thread milling has great advantages in processing accuracy and efficiency, and is not limited by the thread structure and thread direction. For example, a thread milling cutter can process a variety of internal and external threads with different rotation directions. For threads that do not allow a crossover or undercut structure, it is difficult to process with traditional turning methods or tap and die, but it is very easy to achieve with CNC milling. In addition, the durability of the thread milling cutter is more than ten times or even dozens of times that of the tap. In addition, it is very convenient to adjust the thread diameter in the process of NC thread milling, which is difficult to do with the tap and die.

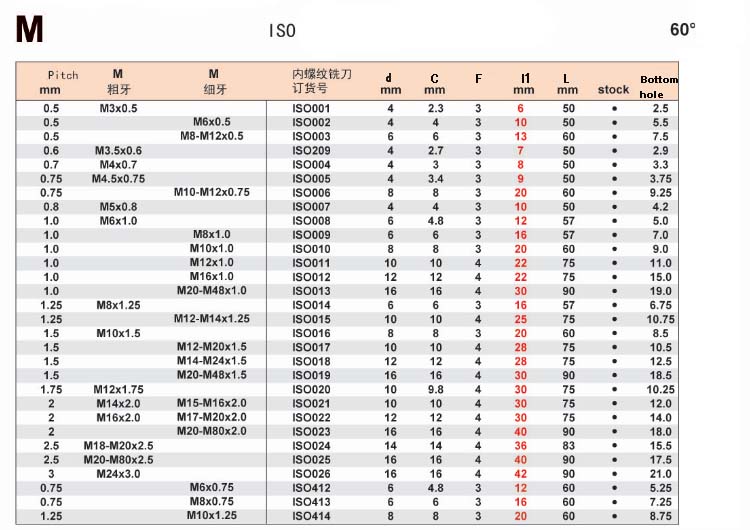

Specifications:

|

Item Grade

|

HRC45

(YG10X )

|

HRC55

(YL10.2 & WF25)

|

HRC60

(Germany K44 &K40)

|

HRC65

(Sandvik H10F)

|

|

Details

|

Grain size 0.7um

Co10% Flexural strength 3320N/mm2 |

Grain size 0.6um

Co10% Flexural strength 4000N/mm2 |

Grain size 0.5um

Co12% Flexural strength 4300N/mm2 |

Grain size 0.5um

Co10% Flexural strength 4300N/mm2 |

|

Coating Classifying and Advantage

|

|||||

|

Item

|

Coating Type

|

AlTin

|

TiAlN

|

TiSiN

|

Naco

|

|

Characteristic

|

Hardness(HV)

|

3300

|

2800

|

4300

|

42(GPA)

|

|

Thickness(UM)

|

2.5-3

|

2.5-3

|

3

|

3

|

|

|

Oxidation Temp.(°C)

|

900

|

800

|

1000

|

1200

|

|

|

Friction Coefficient

|

0.35

|

0.3

|

0.25

|

0.4

|

|

|

Color

|

Black

|

Bronze

|

Bronze and gold

|

Blue

|

|

|

Advantages

|

High heat stability

|

Normally cutting

|

Suitable for heavy cutting, and high hardness cutting

|

For high precision cutting

|

|

|

Suitable for high speed, dry cutting

|

Suitable for cutting mould steel, stainless

steel |

Suitable for high hardness cutting, mould steel processing

|

|||

|

Most suitable for carbide cutting tools, turning insert

|

|

|

|||

Notice:

- Handle with care to avoid impact damage.

- The loading and unloading of milling cutter should be protected with a rag to prevent hands from being injured or the cutter edge from being damaged by falling

- During milling, the milling cutter shall be fully separated from the working object before starting the machine to avoid damaging the cutter due to impacting the working object

- The shorter the distance between the edge of the milling cutter and the bobbin, the better to reduce the vibration of the milling cutter. The length of the cutter should not be too long

- Select the correct and appropriate end milling cutter to mill the working object, and select the cutting speed and feed according to the material of the working object

- When the cutting data is unclear, the feed rate (feed rate) shall be reduced for testing, and then the processing data shall be gradually corrected to achieve the ideal production effect. Do not make rapid advances to cause damage or injury to the milling cutter.

Applications:

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.

![]()

FAQ

1. Flank Wear? Higher cutting resistance,Notch wear on flank,Poor roughness of surface, or deterioration of accuracy.

Soft grades,Excessive cutting speed,Small flank angle,Low feed.

Select a higher,wear-resistant grade,Reduce cutting speed,Increase flank angle,Increase feed.

2. Crater Wear? Uncontrolled chip,Poor surface quality,when finishing High speed processing carbon steel

Soft grades,Excessive cutting speed,Excessive feed,The strength of chip breaker Insufficiet.

Change to a higher wear-resistant grade,Reduce cutting speed,Reduce feed,Select a higher strength chip breaker.

3. Chipping? Sudden fracture of cutting edge(rake face and flank),Instability insert life

Toughness insufficient,Excessive feed rate,Strength of cutting edge insufficient,Instability of the tool.

Select a tougher grade,Decrease feed rate,Increase honing of cutting edge(chamfering to rounding),Increase the stability and setting angle

4. Insert Fracture? Cutting resistance increased Poor surface roughness.

Toughness insufficient,Excessive feed rate,Strength of cutting edge insufficient,Instability of the tool.

Select a tougher grade,Decrease feed rate,Increase honing of cutting edge(chamfering to rounding),Increase the stability and setting angle.

5. Plastic Deformation? Variation of dimension Nose wear,cutting edge drape or passivating.when processing alloy steel Poor surface roughness

Soft grade,Excessive cutting speed,Excessive cutting depth and feed rate,Overheat on cutting edge.

Select a higher red hardness cutting material,Decrease cutting speed,Decrease cutting depth and feed rate,Select a higher thermal conductivity cutting material(CVD+sufficient coolant).

6. Build-Up-Edge? Workpiece dissove with Cutting edge Poor surface roughness when finishing,Cutting resistance increased,Cutting soft materials.

Cutting speed too low,Cutting edge obtuse,Unsuitable tool material. Increase cutting speed,Increase rake angle,Select small sticking force.

Want to Know more details about this product